Research & Development

The opinion leaders in the Medical Science field are a point of reference for Haemopharm, which dedicates a significant amount of resources to the financing of research and development, mostly aimed at the design of delivery systems with advanced functions, complex biomedical devices, suited for the preservation and manipulation of drugs of various types, but also sensitive biologics, such as cells, tissues and organs.

In particular, R&D activities are mainly oriented on three focuses:

Design of new products

The development starts from the study of the therapeutic needs of the users to whom they are intended, with the aim of proposing innovative solutions capable of solving the most frequent problems and opening up new application possibilities.

Innovative and highly performing materials

The company is able to offer cutting-edge materials of the highest quality (in terms of container-content interaction, barrier properties, etc …) suitable for the production of bags and components for the pharmaceutical and medical sector, studying the most suitable solution specific to each project, to ensure the best preservation and stability of the drug.

Implementation of machines for the production of PVC and PVC-free bags and related molds.

Thanks to high-profile engineering know-how and a large and well-equipped internal workshop, Haemopharm is able to manage the entire production cycle, from the construction of customized machines and molds to the creation of prototypes up to the production of finished products.

IN Contract Manufacturing: standard or “tailor-made” solutions

From Feasibility Studies to the Design and Realization of Customized Solutions. Haemopharm’s know-how and highly professional team enable the company to find the best solutions for specific applications, providing companies in the medical and pharmaceutical sector a production organization and capacity with the plus of flexibility. In response to specific needs, Hameopharm is able to design and deliver “tailor-made” products taking advantage of efficient Just-In-Time Production.

The ability to manage all production processes as a single supplier for the customer, from the feasibility study to the realization of the molds up to the sterilization procedures, allows to carry out prototypes and tailor-made productions, guaranteeing excellent quality, in reduced times and competitive price.

- Feasibility and Requirement Analysis

- Procedure Check

- Design and Research for Special Solutions

- Design and Realization of Moulds

- Prototyping

- Testing service and assistance

- Custom-Made Production (Also for Small Quantities)

- Sterilization and Validation

- Printing and Packaging

- Dossier creation support

OUT Contract Manufacturing: a global network of partners

Another Haemophorm’s key areas of expertise are represented by “pharma outsourcing”: filling its own bags taking advantage of the service of “OUT” Contract Manufacturing. Haemophorm has developed a range of Partnerships with global pharmaceutical companies (mostly FDA-approved) that for many years fill the empty bogs manufactured by Haemopharm with different types of sterile liquids.

A specialized division manages and controls the processes of “pharma outsourcing” so that Haemopharm can obtain:

- High quality

- High level of customization

- Local Marketing Authorizations on the finished product

- Choice of the most suitable product (small volumes, big volumes, multi-chamber bags, etc…)

- Low production costs

- Low logistic and transport costs

Aseptic Filling

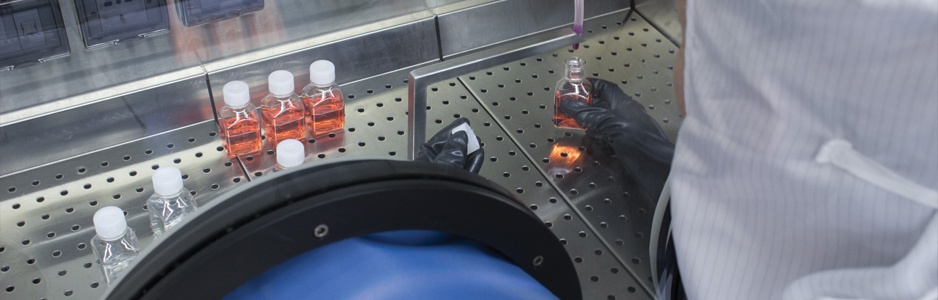

The expansion of the Haemopharm Factory started in 2015, allowed the set up of a Compounding Deportment fully dedicated to the aseptic production of sterile fluids (mainly preservation liquids for the containment of cells, tissues, and organs and small volume custom-made solutions).

The Compounding Department includes an aseptic filling area, equipped with an isolator specifically designed to maintain an aseptic environment throughout the compounding and material transfer processes, and a technological laboratory equipped with advanced instrumentation.

The most stringent levels of environmental control are applied.

During the aseptic processing, device containers and closures are first subjected to validated sterilization by a terminal method and the sterility of the device is achieved by filtering the bulk solution through a bacteria-retaining filter into the final sterile product containers.

System and Quality Control

TAll Haemopharm products are CE-marked since safety is an essential value for the company. Moreover, the company daily gives its full attention to the efficacy and quality of its production processes: the parameters of every system are constantly monitored by the proprietary software system for quality control, and all the procedures are UNI CEI EN ISO 13485:2016 and UNI EN ISO 9001:2015 certified.

Finally, the productive and analytical stages take place in a Clean Room and controlled environment in many classifications, in compliance with cGMP and with UNI EN ISO 14644-1-2-3-4-5-6-7 procedures, and are constantly verified with Audit Methods.

Advanced line monitoring systems.

Haemopharm implemented o pioneering parametric and online camera control that allows 100% inspection of the products.

The proprietary software, dedicated to the monitoring of the process and all the production steps, guarantees top-level product quality.