ADVANCED FLEXIBLE BAGS

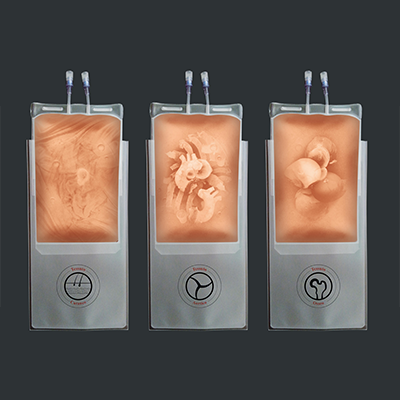

FOR IV DRUG & CELL THERAPY

About us

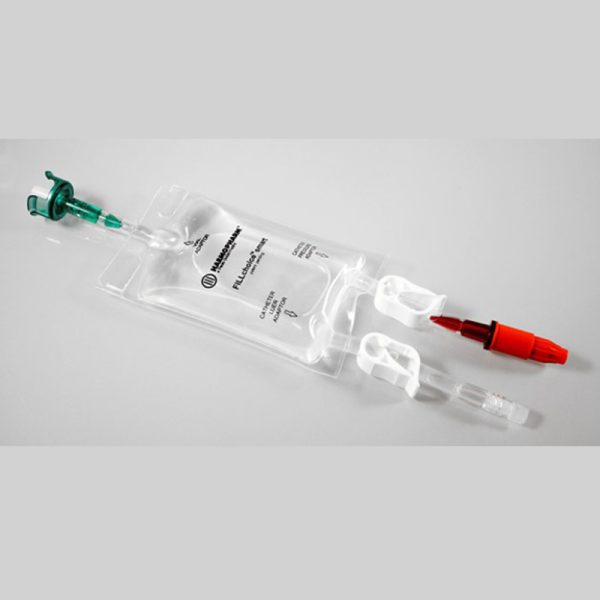

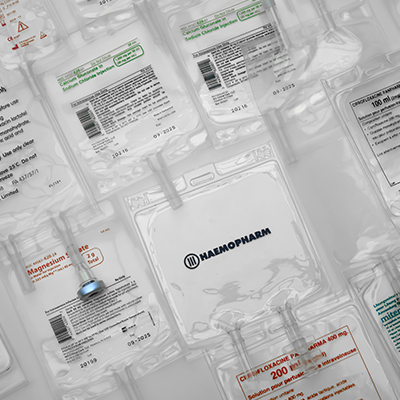

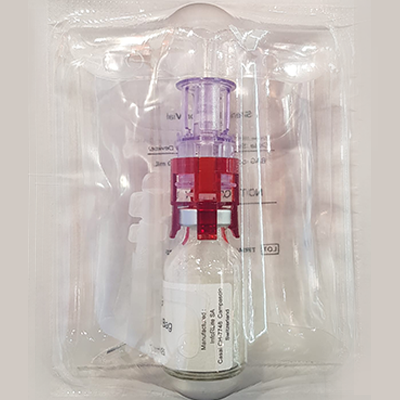

Since 1979, Paolo Gobbi Frattini Group srl has been operating in the market as a specialist manufacturer in the I.V. field, with an offering that includes flexible medical bags for sterile solutions and injectable drugs (in single, multi-chamber and custom-made formats), freezing bags, CSTD/CSSTD, drug reconstitution and delivery systems with innovative proprietary components, including latest generation needle free connectors.

Paolo Gobbi Frattini Group products are widely used in the medical and pharmaceutical fields, in hospitals, pharmacies and in home care.

In over 40 years of activity, Paolo Gobbi Frattini Group has established himself as an international market leader placing four pillars at the center of his vision:

Quality, Innovation, Diversification and Strategic Partnerships.

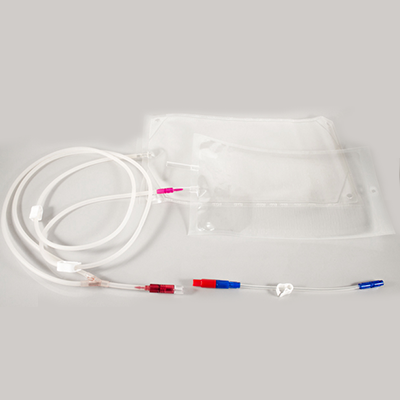

Drug management

Our drug reconstitution and administration systems are designed and manufactured to the highest safety and quality standards to provide added value to drug therapy.

Primary packaging

We support customers in choosing the most suitable materials to ensure biocompatibility with the drug and the best vapour and oxygen barrier.

Custom

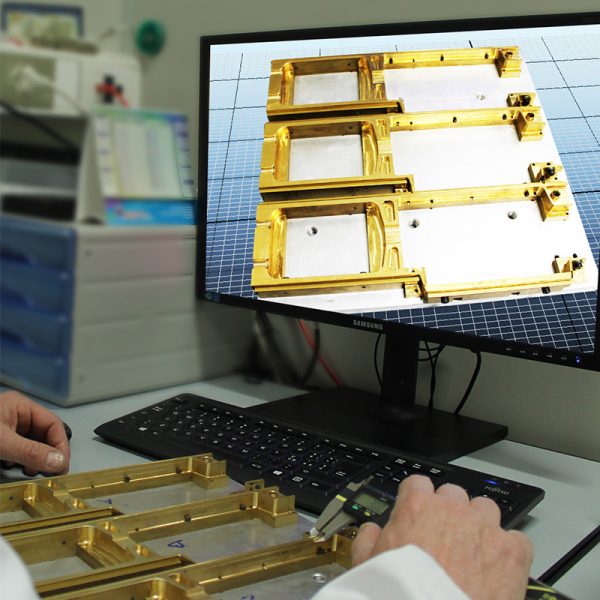

made

A strong R&D department, an advanced technology laboratory and in House production of molds, equipment and production lines are the basis for important personalized service for our customers and meeting clinical needs.

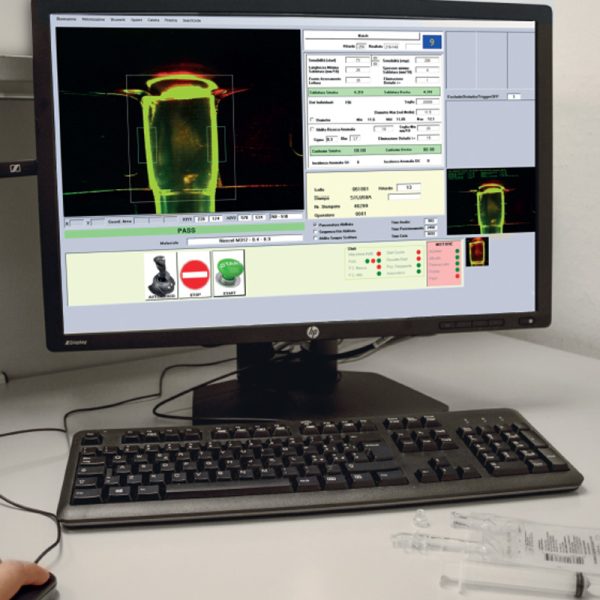

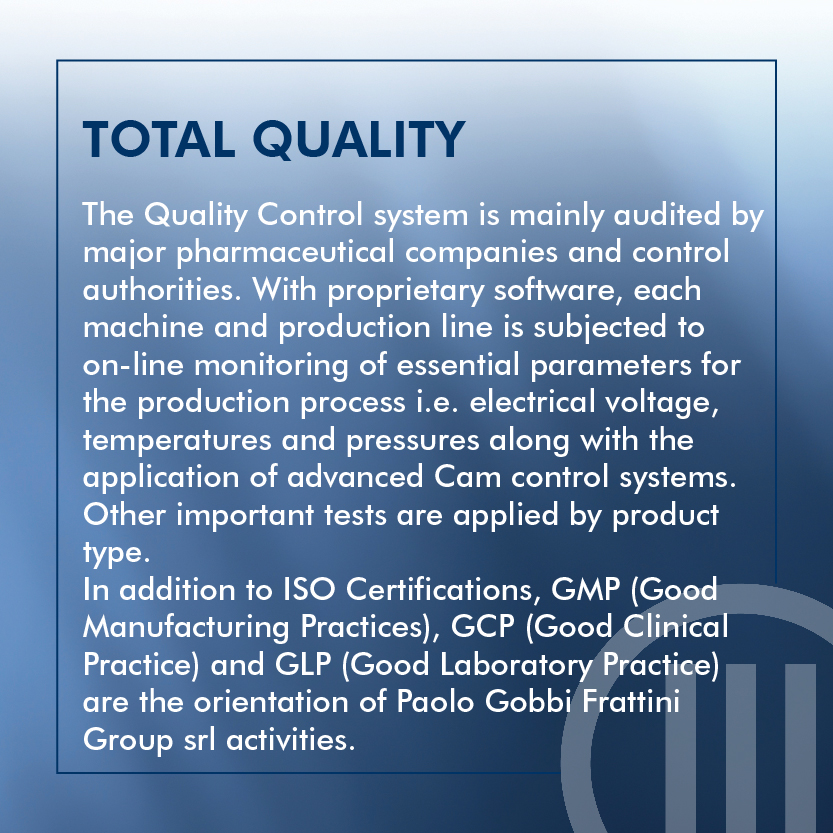

Total

Quality

In addition to ISO certifications,

GMP (Good Manufacturing Practices), GCP (Good Clinical Practice) and GLP (Good Laboratory Practice) are the orientation of our activities.